SYSTEMS OVERVIEW

There are several different electrical and plumbing configurations that can be used in conjunction with the powering, installation, and use of a Nemo Submersible Well Pump. The choice of which system to use is dependent on the specific characteristics of the site, the personal preferences of the site owner, and the overall cost of equipment and installation. But the first decision centers on the power source; whether to choose a Direct Solar or a (solar charged) Battery system.

At first glance, powering directly from a solar module may seem simpler and less costly than powering from a solar charged battery. But presumed advantages may be outweighed by other factors: The pump can only be run when the sun is shining on the module(s), and unless the module array amp output substantially exceeds the amps required to run a pump, the run time will be limited to just the middle couple of hours of the day when the module is at it’s peak output. The time can be somewhat extended by adding a Linear Current Booster (LCB), but these devices can cost nearly as much as a battery, and the system might still need a device to disconnect the pump under low-light or no-light conditions. With a solar charged battery system the module can be sized much smaller, there is no need for an LCB, and power is available to run the pump on demand, during anytime of the day or night. In short, a solar battery powered system is often the best system in terms of both overall cost and practical, trouble-free use. A second consideration in choosing a system is the distance between the power source and the pump. Low voltage wire runs are subject to voltage drop. To minimize voltage drop, either the size (gauge) of the wire needs to be increased proportionate to the distance, or the voltage needs to be increased. Since the cost of wire increases proportionate to the thickness of the wire, it can be advantageous to choose a higher voltage pump for long wire runs.

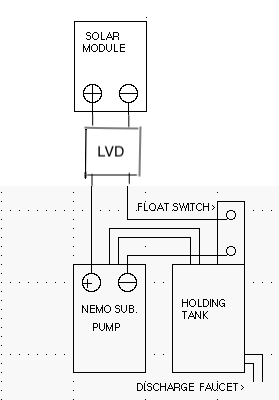

Below are descriptions and diagrams of typical systems, which show how the electrical and plumbing components are connected within each type of system. Please note that, for clarity, the dimensions of components represented in diagrams are (obviously) not in relative scale.

SYSTEM #1: This solar charged battery system is probably the most commonly used set-up for Nemo Submersible Well Pumps. Operation is totally automatic and the system requires no maintenance. The Charge Control / LVD regulates battery charging and also protects the Pump by switching it off (and back on) relative to the voltage level of the battery. Water is pumped to the Holding Tank and as water is drawn from the Tank by gravity feed to the faucets, the water level in the Tank rises and falls and the Float Switch, mounted on top of the Tank, automatically turns the Pump off and on as required, to maintain the supply stored in the Tank.

SYSTEM #2: At many shallower well sites, pumping directly from a Nemo Submersible Well Pump into a pressure tank can eliminate the need for a holding tank (and also eliminate the need for a booster pump as described in System #3). However, to use System #2, the total system pressure should be well below the maximum rated pressure of the pump. The Total System Pressure is the pressure required to lift the water (each 2.31′ of head = 1 p.s.i.) to the pressure tank, PLUS, the setting of the pressure switch on the pressure tank (30 to 50 PSI). If this sum is conservatively calculated to be below the maximum 100 PSI rating of the pump, then System #2 is a viable option for a simple, fully automatic set-up that would provide pressurized water at all connected faucets.

SYSTEM #3: This system uses two pumps and two tanks; a Nemo Submersible Pump to fill a Holding Tank and a Flojet 4300, surface mounted “booster” pump (with built-in pressure switch) to charge a Pressure Tank. Using the FJ4300 to provide pressurized water at faucets alleviates the work load of the Nemo Sub Pump. This is especially advantageous where the Nemo is required to use most of it’s rated PSI for lifting from deeper wells. Another advantage is that the Flojet 4300 ( being a surface mounted pump) is more easily accessed and serviced than the Nemo Sub, and regardless of the well depth, the (more expensive) Nemo will last longer and work better if it is not required to both lift and pressurize the water.

SYSTEM #4: In this Direct Solar system the output amperage of the Solar Module should be at least equal to the amperage draw of the Nemo Submersible Pump, which varies depending on the Total System Pressure of the particular installation. That would enable the pump to run at it’s rated voltage for the limited period of time in the middle of each sunny day that the module is producing at it’s peak output. To extend the run time beyond this window would require additional options; a proportionately larger solar array and/or a LCB device. To prevent the Pump motor from running too slowly, stalling, and overheating, a Low Voltage Disconnect (LVD) is installed between the Module and the Pump.

SYSTEM #5: Compared with other systems, this may not actually qualify as a “system”, but it will pump the same amount of water at a fraction of the cost.. To put a name to it, it might be called the “Minimalist System”. The diagram is fairly self explanatory, but it is simply a Nemo Pump, attached to a length of hose and a set of wires, with an auto lighter plug (correctly polarized) connected to the end of the wires. Plug it into the lighter socket of a motor vehicle to turn on the water, unplug it to turn off the water.

SYSTEM #6: This system is simply the use of a Nemo 115 Volt AC/DC pump for long wire runs, which (since higher voltage means lower voltage drop) effectively reduces the size and cost of the wire. The Nemo 115 Volt AC pump has virtually the same performance characteristics, including operating wattage, as the Nemo 12 Volt and 24 Volt DC pumps, but in off-grid applications the Nemo 115 Volt AC/DC pump needs to be operated from a 115 Volt AC power source, such as a small (150 watt minimum) DC to AC inverter or an AC generator (it will also operate directly on 115 Volt DC power). No diagram required here; it is simply a matter of connecting the Nemo 115 Volt AC/DC pump to an inverter that is powered by a battery, or by connecting the pump directly to an AC generator. For these AC operated pumps, wire gauges between a minimum of #14 AWG to a maximum of #10 AWG would typically suffice for distances up to 275 feet.